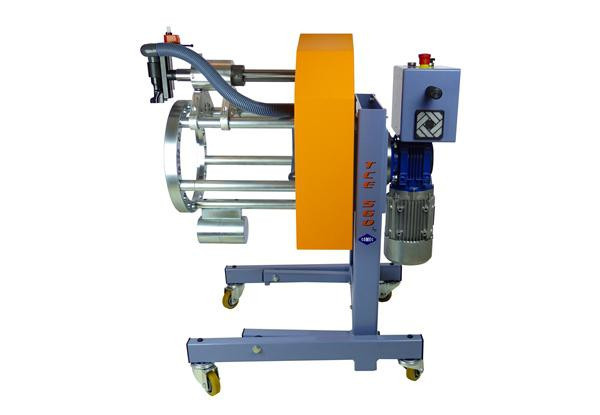

The TCE560 is the perfect machine for turning brake shoes on heavy duty trucks.

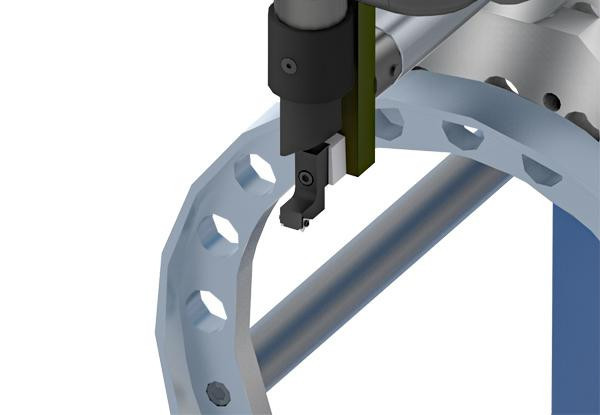

The machining is operated directly on the gear unit hub axle or by using suitable accessories on conventional axles (even with mounted internal bearing).

The machine is supported by an height-adjustable, tilting and self-aligning patented carriage, which ensures quick and easy fitting operations.

The high speed rotation of 90 rpm (on both ways), together with the sequential feed of 0.6 mm/rev and the adjustable control stop, ensures short machining cycles, while providing for excellent surface finishing, cylindricity and concentricity precision.

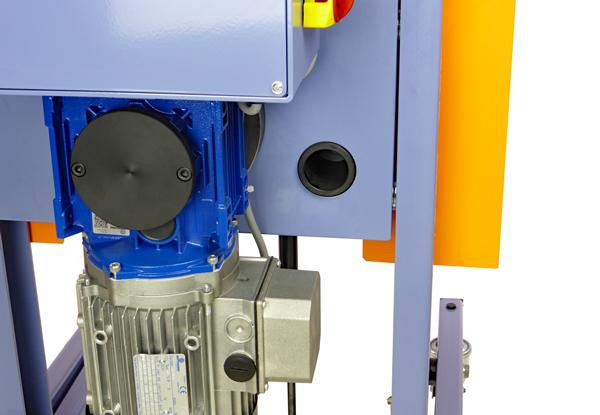

The oversized gearmotor (1.8 kW) enables the machine to work under the hardest conditions (double or triple differential gear, transmission shaft connected, frozen oil, etc.)

The soft-start electric device controls the power, thereby starting the machine gradually with no jerks.

The standard equipment is complete with the practical reference dimension reader and the dust collector housing.

Specific accessories for the centering or to simplify and speed up the manufacturing process are available upon request.

Tilting and self-aligning carriage for positioning

Adapter ring for Mercedes/Man hubs

Electronic “Soft-start” device for smooth starts

Setup of turning diameter through reference dimension reader

Double insert toolholder L=30 mm

Double insert toolholder L=50 mm

Dust collector housing

Automatic feed stop

Safety guard

Wrench set

Rotation Speed 90rpm

Intermittent feed 0.6mm/rev

Minimum turning diameter 230mm

Maximum turning diameter 480mm

Maximum brake shoe depth 290mm

Motor power 2.5hp (1.8kw)

Dimensions (LxWxH) 670x950x1150mm

Weight 160kg